Reduce risks from undocumented and unmaintained hose assets

NOTE: The sponsor of this content may contact you with more information on this topic (if you arrived here from the BIC Industry Report e-newsletter). Click here to opt out from sharing your email address with this sponsor. (This link will not unsubscribe you from any other BIC email list).

In today’s process manufacturing facilities, the need for safe, dependable hose assemblies is more important than ever. Proper hose assembly maintenance and documentation are necessary throughout the petrochemical industry– from refineries to chemical plants. Process, transfer, loading and unloading.

However, with their growing and varied responsibilities, maintenance and operations staff at these process manufacturing facilities often overlook the importance of having a structured, ongoing hose maintenance program in place. Hose maintenance often occurs only after a failure, which can lead to safety hazards, injury, unexpected downtime, and fines.

While asset management strategies and systems have been widely adopted with larger operating machinery and equipment in the manufacturing and processing industry, these same proven processes have not been adopted as broadly for industrial hose and coupling applications in these facilities. This need not be the case today.

DIGITAL TRACKING SOLUTIONS

New asset management technologies are available today, specifically designed to address questions about safety and cost of ownership issues related to managing a large numbers of hose assets.

One solution, OnGuard® Asset Management, available through local industrial distributorships under the family of Singer Equities, offers a proven system to help chemical facilities proactively manage and maintain their hose assets.

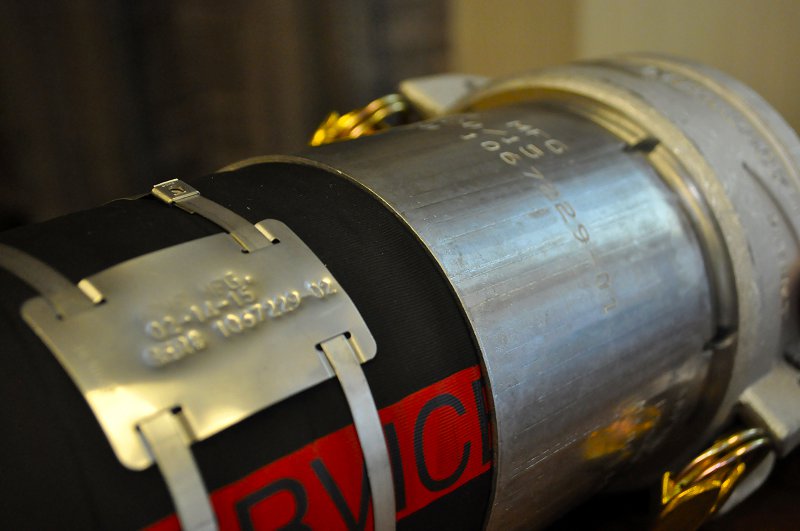

The OnGuard hose management solution tags each asset, tracks when the system goes into service, and alerts the facility when service or replacement is necessary. This is done through a cloud-based hose tracking database, which stores important data such as type of hose, manufacture date, test certifications, serial number, location in facility, inspection, and re-testing alerts.

This solution can also be incorporated with plant piping or safety standards to become an integral part of any reliability and maintenance program. OnGuard also allows users to schedule customized reports in multiple formats and provides a structured, documented procedure for asset maintenance, leading to less downtime, safety hazards and fines from unchecked and unsafe systems.

AFFORDABLE TRUSTED SOLUTION

There is no charge for the OnGuard asset management system itself. Customers do pay for the cost of the hose tags, which range from simple metal tags to those with radiofrequency identification (RFID)-embedded chips. OnGuard also offers a daily fee service for on-site asset inspections and testing that can last just one day or several days, depending on the volume and complexity of the customer’s hose assets.

WHY IS THIS IMPORTANT?

Consider these questions:

- Are we using the correct hoses for our applications?

- Are our hoses safe and in compliance?

- Have our hoses been tested?

- Are our employees safe?

- Where is the documentation on our hoses?

- Can I locate our hoses?

- Are our hoses properly installed?

- Are our hoses tagged and well-maintained?

- Is our equipment safe?

OnGuard provides peace of mind through:

- Digital tracking of hose assets

- Enhanced reliability and process safety capabilities

- And better predictive maintenance for hose assemblies

As a trusted domestic distributor, we offer premium hose and fitting brands along with industrial hose application expertise built from decades of service in the processing and refining industries. Using our OnGuard Asset Management service, we will partner with you to inspect, test, tag and track your critical hose assemblies.

WHY RISK IT?

Putting an effective asset management program in place for hose can help protect against injury, unexpected downtime, fines and more. Planned inspections and a properly implemented management system for your hose assets is the first line of defense against:

- Hose Failures

- Leaks/Spills

- Costly Downtime

- Accidents Injuries

- OSHA/EPA Fines

FREE ONSITE EVALUATION

Contact us today to schedule a free, no-obligation hose management and safety evaluation at your facility. Call 877-483-6577 or visit www.alwaysbeonguard.com